Previously I did a quick overview of the TechnoTomato outdoor aeroponic tomato growing system. Today I wanted to provide a quick rundown of the nutrient delivery system; otherwise known as plumbing.

I am using a high pressure aeroponic system as opposed to low pressure or fogponics. A high pressure system typically operates in the 100psi range and uses 0.0124″ misting nozzles that will deliver a 50 micron droplet size at 100psi. I chose this design based on research done by NASA in collaboration with AgriHouse and CU Boulder which showed that short bursts of 50 micron droplets with long intervals between sprays gave the best results.

A brief history of aeroponics: Aeroponics is a technique for growing plants without soil or liquid water. It’s incorrect to say that aeroponics doesn’t use water, it does, just not large volumes of it as you would in hydroponics. Aeroponics suspends roots in air where they are periodically sprayed with nutrient solution to supply water and nutrients to the plant.

Aeroponics were first developed in the 1920’s to make it easier to study the fine structure of roots. The macroscopic part of a plants roots are essentially inert material that serves as a supporting structure and water conduit but don’t absorb water or nutrients directly. All the interesting stuff happens at a microscopic level at the very ends of the finest parts of the root. These fine structures are far too small and delicate to survive being pulled out of the soil and they don’t develop the same way in liquid water but hanging them in air and misting them with fine droplets of water allows normal development of the roots in an environment where they can be studied.

Aeroponics really didn’t make it out of the laboratory until 1982 when it made an appearance in “The Land” pavilion at Disney’s Epcot Center. This exhibit continues to be a serious research facility studying hydroponics, aeroponics and aquaponics. In the 1990’s NASA became interested, for obvious reasons, in aeroponics as a way to grow food for space missions. My interest in aeroponics was sparked when I ran across a company near where I live called Agrihouse. Agrihouse was awarded a NASA SBIR grant in 1998 to develop aeroponics. Agrihouse completed this work in cooperation with Colorado University aboard the Mir space station in 1998.

One of the primary limiting factors for plant growth is how much oxygen the roots can get from their surroundings. When growing in soil the roots are limited to what oxygen can penetrate the soil to the depth of the roots. If the soil is well turned and not too wet or dense the plants can grow pretty well but soggy soil or dense clay can severely inhibit growth. Also too much organic material in soil can encourage aerobic bacteria and fungi that compete for oxygen in the soil.

Similarly hydroponics, where roots are suspended in water, can make it difficult for roots to get access to oxygen. If water isn’t well aerated because it is too warm or has microbial activity competing for oxygen it can affect the plants.

Aeroponics has the advantage that the roots are suspended in air where they have essentially unlimited access to oxygen. There are several variations on this theme but they all rely on applying only enough nutrient solution to keep the roots supplied with water and nutrients but not so much that access to oxygen is limited.

One of my goals was to build a system that did not recirculate the nutrient solution. I chose to do this because my initial attempt in the summer of 2017 showed that recirculation introduces bacteria into the nutrient reservoir. Also recirculation causes the nutrients to become depleted before they run out.

The difficult part is delivering enough water and nutrients to keep the plant hydrated even under extreme heat while not putting so much water on the roots that water drips off of them. To this end I’ve chosen to use a very short spray pulse of about 300 milliseconds at an interval of no less than one minute between pulses and no more than 30 minutes between pulses. Of course the valves, even though energized for only 300 ms, take longer to open and close. Probably closer to a half second total.

My first attempt at this employed vertical 1/2″ tubes with holes threaded for 10/24 UNC brass spray nozzles. Even with a 300 ms timing these things were going through about a half gallon of water per hour per plant. Yikes!! The problem being, of course, that a two foot long 1/2″ inside diameter tube has a volume of over four and a half cubic inches (77 ml) that has to be pressurized to 100 psi in less than a second in order for the nozzles to function as desired.

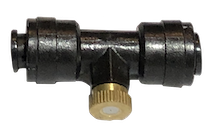

Multiply that by four and you have 18 cubic inches (308 ml); completely unworkable, particularly when you consider that air leaks into the tubes through the spray nozzles during the interval between spray pulses. So even though the half inch tube is much cheaper and more convenient than the quarter inch press fit tee’s with nozzles the performance is abominable.

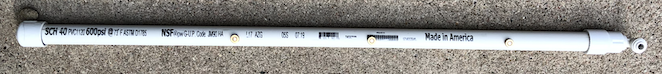

The alternative is the quarter inch press fit tee’s on quarter inch tubing. Even with several nozzles with six inches or so of tubing between them you only have a measured volume of less than 5 ml. The spray system with quarter inch tubing and tees is far more responsive and consumes only about 100 ml of nutrient solution per plant per hour even on a day that reaches 100 ℉.

The only fly in the ointment, so to speak, is that, unlike the rigid half inch PVC pipe with nozzles inserted, the tee’s are free to rotate on the tubing and can become misaligned. The 300 ms, 100 psi spray pulses produce quite a bit of thrust at the nozzles causing the tubing to flex and twist. So far the problem hasn’t been too terrible but I do find nozzles out of alignment.

The solution I’ve devised is to make alignment tubes consisting of half inch PVC pipe with a three eighths slot milled down one side of the pipe. The tees with their nozzles slide nicely into the tube with the nozzles held in alignment in the slot. This also makes it really easy to pull sets of nozzles out for inspection or replacement and back in again.

A set of four tubes is held in place in a frame that holds a plant suspended in the middle with its roots hanging in in the air. The spray tubes are arranged at each corner with the spray nozzles aimed at the roots in the center. The frame is constructed of half inch PVC pipe and PVC furniture fittings and is two feet tall by 16 inches on a side. Sitting at the bottom and top is a sealed wood panel with a hole in the center big enough for a two inch mesh pot and holes in the corners to slide the spray tubes through.

This about sums up the design of TechnoTomato’s plumbing and overall structure. In my next post I will discuss the sensors and control of this system. Until then happy techno gardening.